28

2025

-

07

King's Little Classroom | Secret Revealed! Industrial Fans Contain "Aviation Genes"

所属分类:

日期:

2025-07-28 14:45:18.147

Slower speed, "cooler" feeling

King-size ventilation, a refreshing breeze for the world

The electricity bill is shocking!

Large-space ordinary fans are increasingly inefficient?

Aviation-grade giant fan, airplane propeller black technology

Energy saving 30% Still creates hurricane-level coolness!

01.

Background and Origin

The design of HVLS (High-Volume, Low-Speed) fans can be traced back to the late 20th century's agricultural needs in the United States, with the core goal of solving cooling problems in high-temperature environments.

1. Needs and Birth: In 1998, the Department of Agriculture at the University of California, Riverside, raised the issue of decreased milk production in dairy cows due to heat stress in the summer. In 1999, Boyd successfully developed the world's first HVLS fan.

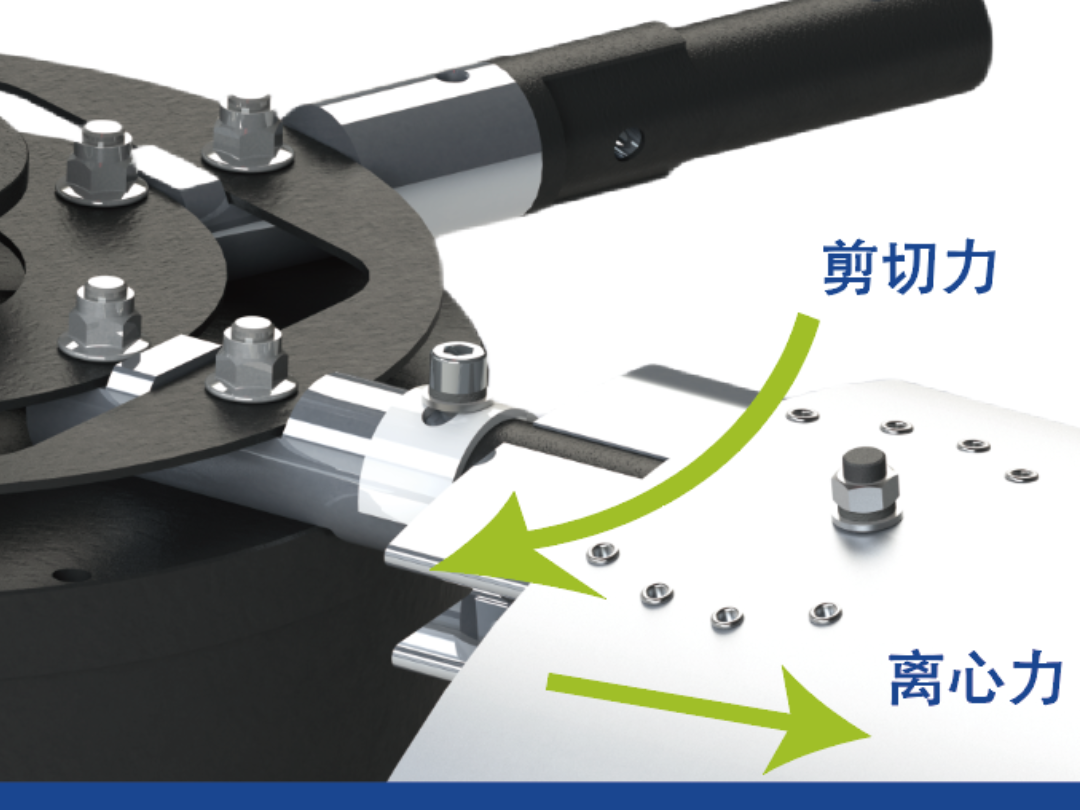

2. Design Roots: Drawing on the aerodynamic principles of aircraft propellers, adhering to the concept of low energy consumption and high performance, pursuing large air volume at low speeds.

3. Prototype Characteristics: With a diameter of 7.3 meters and a full-load air volume of 16130 (m³/min), it uses slow rotation of the blades to push a large amount of air downwards, forming a three-dimensional micro-breeze system similar to natural wind

02.

Core Technological Breakthroughs

1. Cross-Industry Application of Technology: After initial use in dairy farms, its energy-saving advantages (single unit covers 1200-1500㎡, power ≤1.5kW) were quickly discovered by the industrial sector, leading to cross-industry solutions.

2. Core Adaptation Challenges: Adapting aviation principles to large-scale ground equipment to achieve reliable operation of large sizes at low speeds.

3. Key Technological Design: Using high air volume and low speed (forming a closed-loop airflow cycle, stirring temperature stratification, and a 5-8℃ perceived temperature reduction), and applying airfoil blades (experiments show that airfoil blades increase air volume by about 20% and reduce energy consumption by more than 15% compared to traditional straight blades).

03.

Applications and Technological Expansion

1. Core Advantages: Integrating aviation principles to establish the core advantages of large air volume, low energy consumption, and gentle airflow.

2. Scenario Expansion: Starting from farms, based on the core needs of industrial ventilation. Since the 2000s, HVLS fans have been widely used in factories, warehouses, stadiums, and other high-space areas, replacing high-energy-consuming air conditioners or traditional fans.

Conclusion

The design origin of HVLS fans is a technological revolution driven by agricultural needs. Its core innovation lies in achieving airflow circulation and ultra-wide coverage through the combination of "large diameter + low speed + airfoil blades", becoming a key equipment for industrial energy saving and comfortable environment construction.

Recommended News

400-086-9230

400-086-9230

联系我们

联系我们

sales@dawangfanschina.com

sales@dawangfanschina.com